Colombia Natural Strawberry Catiope

Elkin Guzman’s Strawberry Natural is a showcase of controlled fermentation, crafted at El Mirador and processed at Clearpath Coffee Mill. This Catiope varietal undergoes an intricate co-fermentation process, where carefully selected cherries are first treated with a citric acid wash before undergoing a 176-hour fermentation with a caramelized strawberry mother culture and brown sugar. This technique enhances the coffee’s lactic acidity, deepens its strawberry jam sweetness, and adds layers of floral complexity. The drying process, spanning 15 days. Grown at 1,550–1,700 m.a.s.l.

What's included in each experience

TAKEOUT BOX - ALL THE EXTRAS

The Takeout Box comes with:

- A 200-gram bag of coffee

- One fortune cookie or Hi-Chew

- A few stickers

- One packet of instant coffee

- One custom brewing water packet from Third Wave Water

- A detailed coffee card

JUST A BAG

This option contains:

- One 200-gram bag of coffee

- One instant coffee packet

- One detailed coffee card

1 KILO BAG

This option contains:

- One 1000-gram bag of coffee

- Two instant coffee packets

- One custom brewing water packet from Third Wave Water

- One detailed coffee card

2 KILO BAG

This option contains:

- One 2000-gram bag of coffee

- Two instant coffee packets

- One custom brewing water packet from Third Wave Water

- One detailed coffee card

Coffee Info

Location: Hulia

Country: Colombia

Producer: Elkin Guzman

Mill: Clearpath Coffee Mill in Pitalito, Huila

Process: STRAWBERRY NATURAL

Varietal: Catiope

Harvest date: Semester Q2 2024

Volume Purchased:150

About the farm: The harvested coffee cherries undergo a disinfection process with a citric acid solution. We then begin our co-fermentation process by separating a 40-liter mass in a 200-liter can of mother culture, which has a caramelized strawberry mixture and takes 4 days to reach its optimal state. During fermentation, brown sugar is added as an energy source, and the pH is monitored for ideal conditions. The selected cherries (150 kg) are placed in plastic tanks for an initial 80-hour sealed fermentation to activate microorganisms and release CO2. Following this, the sourdough is added at a 10-liter ratio per tank for a 96-hour co-fermentation. After 176 hours of total fermentation, the coffee is moved to the drying area, left in thin layers for the first 3 days, and then turned every 3 hours until the moisture content reaches 10.5-11%.

Drying time: 15 days (11 days raised beds and 4 days in mechanical dryer)

Drying Temperature: between 20 and 40 degrees in raised beds Celsius – 35 to 40 degrees in the mechanical dryer

Humidity: 12%

Density: 570

Water Activity: 0.63

Stabilization: 20 Days

Elevation: 1550-1700 masl

Temperature: 15-32’C

Total trees: 90000

Other trees: yuca, plantain, limes, guama, guava, coffee walnut, another local native trees.

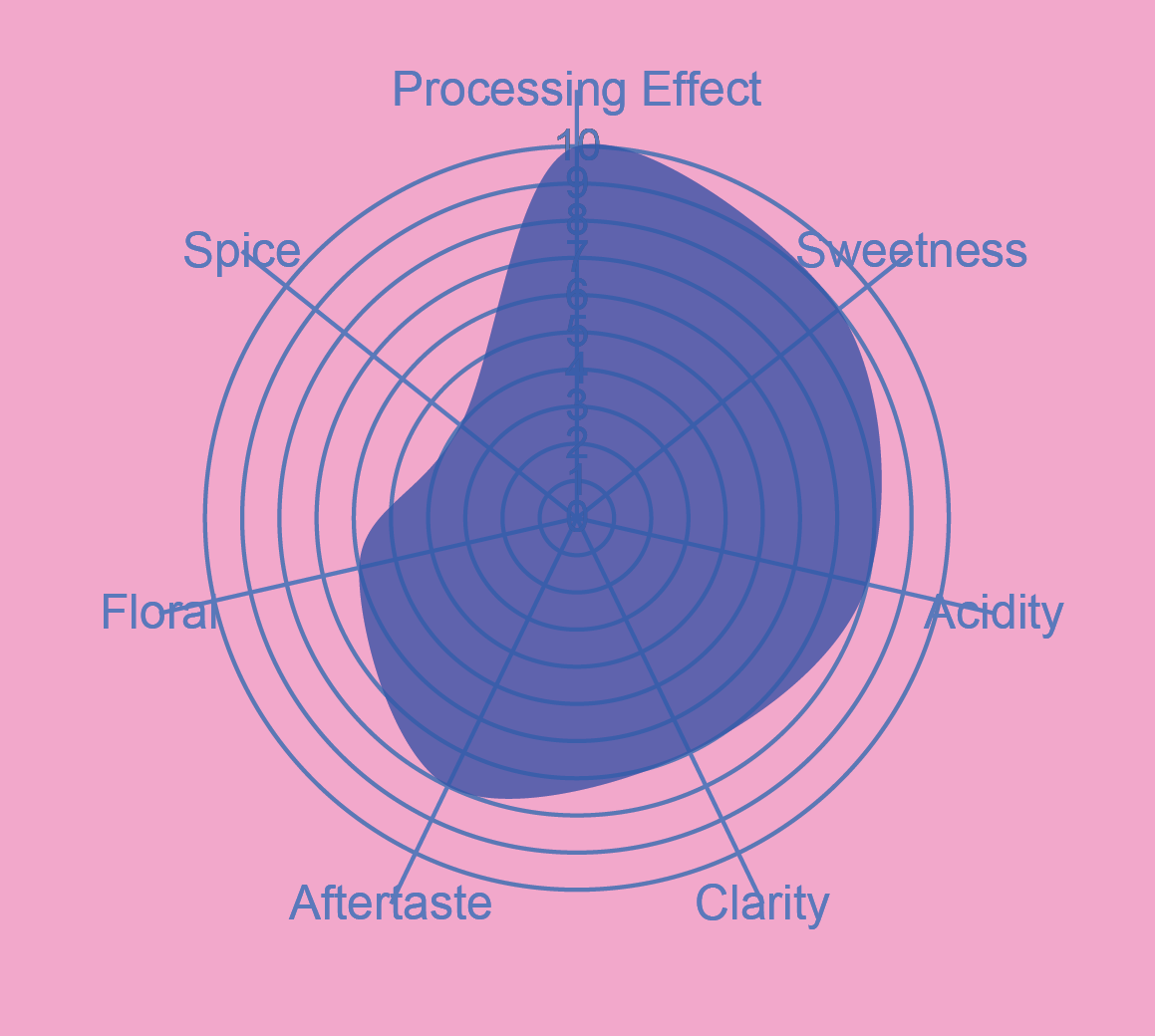

Taste Cup Profile

Strawberry Jam, Lactic Acidity, Chocolate Mousse, Floral

Processing Cup Effect : 10

Sweetness : 9

Acidity : 8

Clarity : 7

Aftertaste : 8

Floral : 6

Spice : 4

Internal Cup Score : 88

Bean: 73 Ground:110

Transparency cost

Here, we share what the producer or farm manager is comfortable with sharing, like export, milling, and pickers' pay, as it helps to know who you support. We always share at minimum Farmgate, FOB, and our cost.

Farmgate : $7.31LB / $16.08KILO

FOB : $7.75LB / $17.05KILO

Farmer's % : $7.31LB goes directly to Elkin Guzman

Our Cost Of Green : $8.55LB / $18.81KILO

Roasted cost 14% : $19.74LB / $21.44KILO

Packaging : $1.98

Luminous Labor : $28 HOUR

Ship Dates

We pack all orders and then ship them out at 9 AM on Monday through USPS. For international orders, we use DHL, which ships at 11 AM on Monday.

Tracking information is sent to your email. For any issues, please reach out to us.

We also roast some batches on Saturday on Instagram Live, so you can tune in, ask questions, and learn about the process.

Brew Recipe Tool

Producer Q & A

How did you come into working in coffee?

I grew up surrounded by coffee farms in Palestina, Huila, so you could say it’s in my blood. I’ve been involved in coffee production for over 15 years now, and it was my curiosity about fermentation and coffee processing that really drove me deeper into this world. My family has been involved in coffee farming for generations, but my passion lies in pushing boundaries and experimenting with different fermentation methods to unlock new flavors.

What makes this harvest or lot different from others?

This harvest is special because we’ve refined our controlled fermentation processes even further. We’ve developed specific protocols to bring out unique flavor notes, and we’ve been able to apply these to both traditional and exotic varietals. This particular lot showcases the balance between innovation and tradition, with clean, distinct flavors that reflect our deep commitment to quality.

What would you say separates your coffee from others?

Our coffee is set apart by the meticulous attention we give to fermentation and post-harvest processes. We’re constantly experimenting and fine-tuning techniques that result in unique and diverse flavor profiles. Each coffee we produce carries its own signature, reflecting the care, innovation, and research behind it. We also focus on sustainability and traceability.

What does your day consist of managing the farm or farms?

My day usually starts early with a check on the fermentation tanks and drying beds, ensuring that the processes are going smoothly. I’m constantly monitoring the coffee cherries during their different stages of fermentation. Communication with my team is key, we work closely to oversee every detail, from picking the ripest cherries to controlling fermentation times and temperatures. I also dedicate time to research and development, always exploring new fermentation techniques to keep improving.

What opportunities are you looking for from people who buy your coffee or work with you currently?

I’m always interested in buyers who are as passionate about innovation and quality as I am. I’m looking for long-term partnerships with people who appreciate the complexity of the processes we use. It’s rewarding to collaborate with partners who provide feedback, share insights, and help us refine our methods. Transparency and trust are important to me, and I seek those values in any collaboration.

Where does your sense of passion for coffee come from?

My passion comes from the endless possibilities that coffee offers. Coffee is alive, it evolves, changes, and surprises you every season. My passion grew even stronger when I started experimenting with fermentation and saw how different techniques could enhance flavors in ways we hadn’t imagined. Every harvest is a chance to innovate and discover something new, and that excitement keeps me driven.

Are you looking to grow relationships with long-term partners?

Yes, long-term relationships are essential to my work. They allow for deeper collaboration and a mutual understanding of expectations and goals. I believe that working closely with long-term partners helps both sides improve, it’s not just about selling coffee; it’s about creating a shared journey towards better quality and sustainable production.

Feel free to share anything on your mind about the industry or yourself. We sell not just to consumers but to the industry, which often looks at what we buy and tries to buy it too, benefiting everyone.

I believe the coffee industry is evolving rapidly, especially in terms of how producers and buyers collaborate. There’s more appreciation now for the complexity behind coffee production, particularly with innovative processes like fermentation. I’m hopeful that this trend will continue, allowing producers like myself to push the boundaries of what coffee can be while also ensuring that sustainable and fair practices become the norm. And finally, I want to thank you and your customers for buying our coffees.